THE ENERGY TUBER - A VERY HIGH YIELDING, SUSTAINABLE FEEDSTOCK FOR FUEL

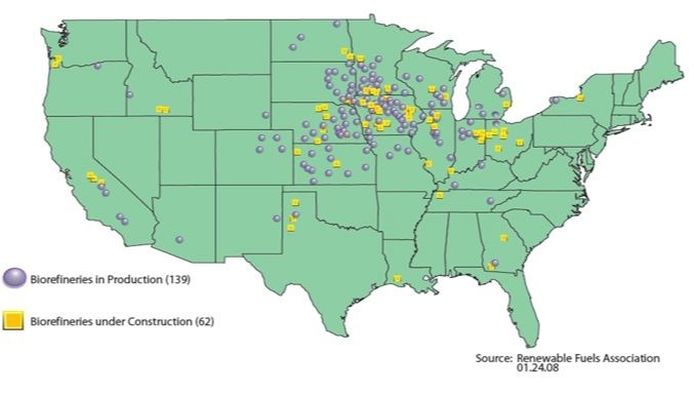

Energy Tuber Allows Expansion of

American Production Facilities to Sun Belt States

American Production Facilities to Sun Belt States

- There are few fuel ethanol biorefineries in Sun Belt, despite long growing season, adequate rainfall, and abundant farm land, due to the lack of an adapted feedstock crop – until NOW.

- The Energy Tuber grows well from NJ to FL, across the southern states to CA

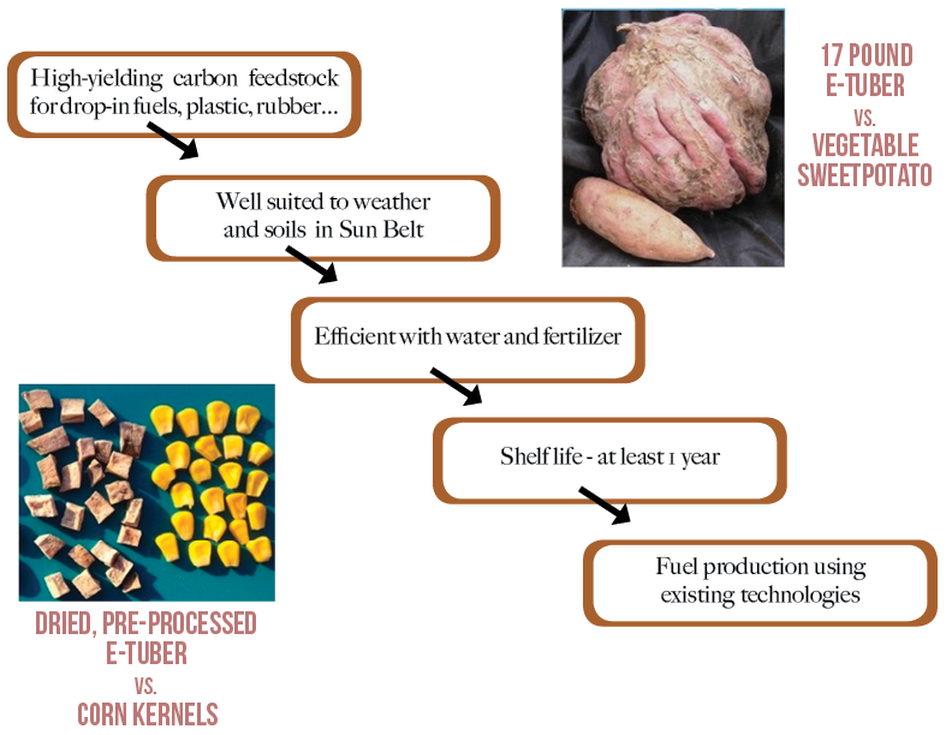

Requirements for the Ideal Feedstock for Biofuels and Bio-based Products: |

Produce high yields of low cost sugar; be cost-competitive with fossil fuels |

Qualify as an ABF to receive subsidies and RINs (to build infrastructure to compete) and as a transitional feedstock for existing corn plants |

Produce abundant supply near processing plants and users – Adapted to the sunbelt |

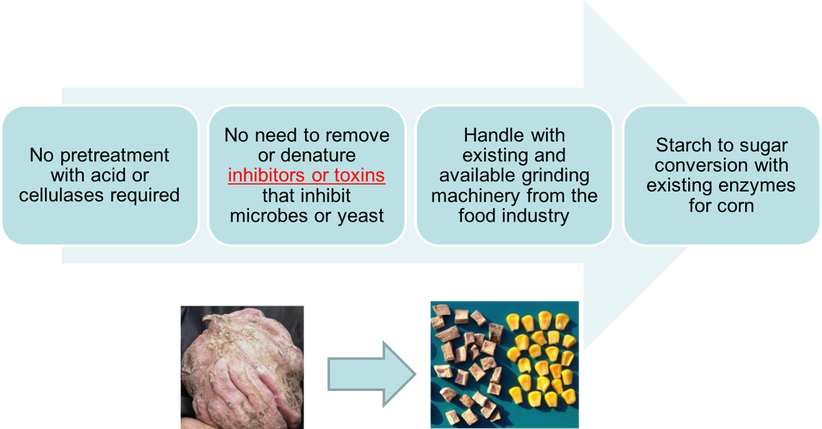

Be easily converted by microbes and yeast without inhibitors to microbe growth |

Integrate easily into today’s technology (such as corn fermentation plants) |

The Energy Tuber is ideal

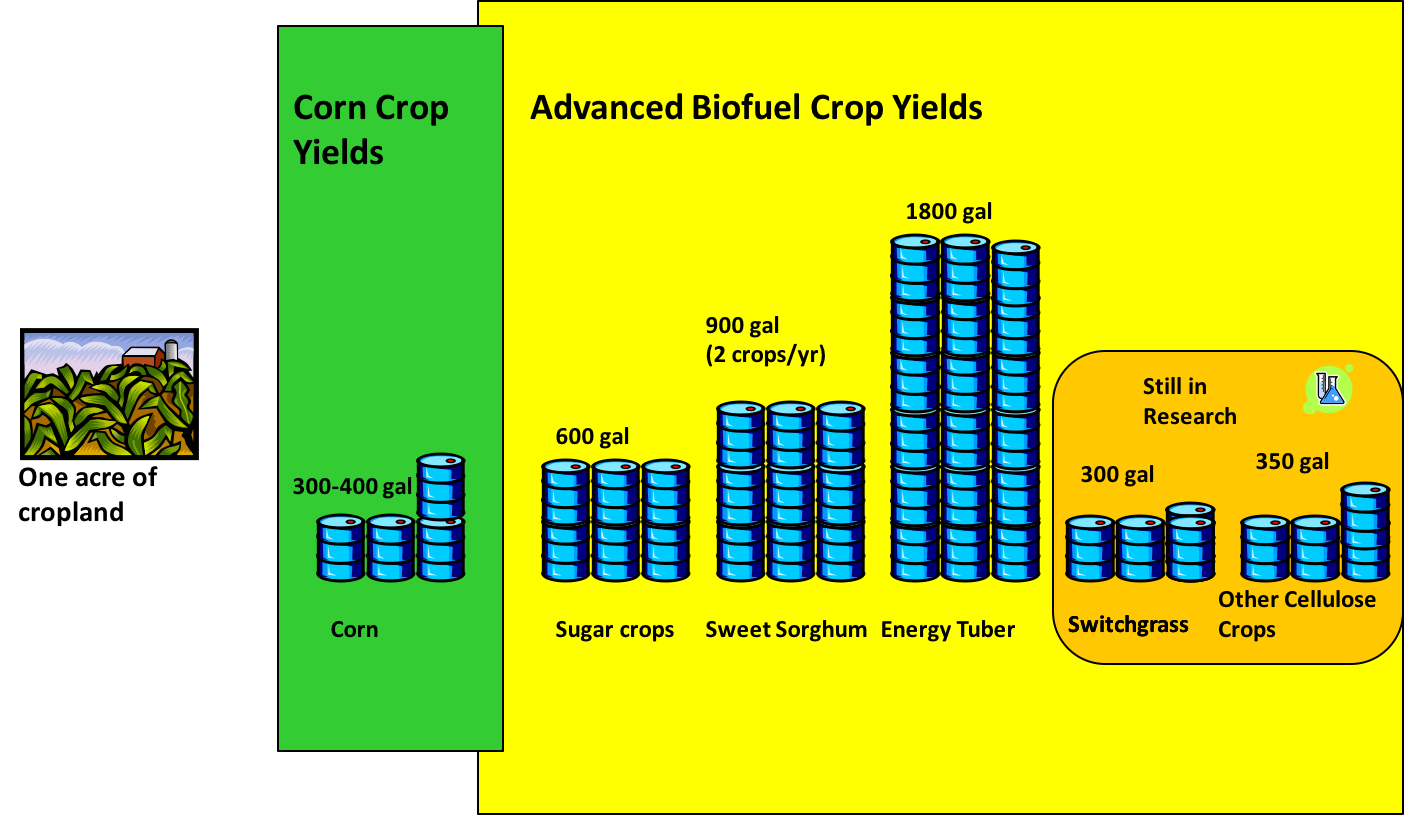

Ethanol Crop Yield Comparison |

Corn vs. Advanced Biofuel Crops |

CORN |

ENERGY TUBER |

CELLULOSIC |

400 gallons/Acre |

1800 gallons/Acre |

300 gallons/Acre |

High need for water/fertilizers succeeding commercially |

Low need for water/fertilizers ready to succeed commercially |

In research stage, has yet to succeed commercially |

Grows best in MidWest USA with limited population |

Grows best in all Sunbelt states |

Very costly to commercially convert to fuel |

The Energy Tuber, processed with today’s technology, acts as a drop-in-feedstock for corn ethanol plants. |

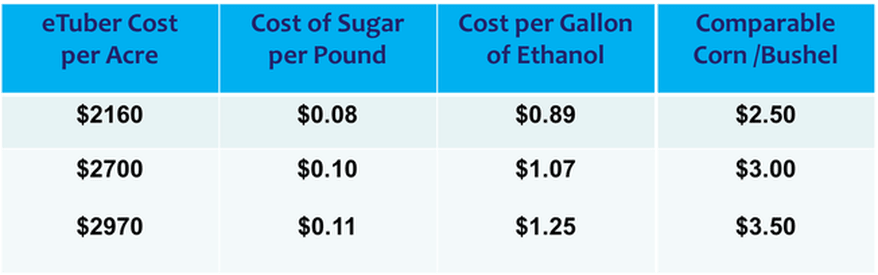

Energy Tuber Feedstock Production Cost of Sugar from Energy Tuber and Ethanol Output Vs. Corn |

- Calculations based on 45 wet tons per acre, 33% dry wt., and 85% starch and sugar

- Current estimates are $0.08-0.10 per pound sugar, which can be reduced through

further mechanization of the crop planting and harvesting. - Total production costs vary slightly by region. Costs include farmer profit.